Watch our newest videos

Rockpecker Drilling Products & Accessories in 3D-Simulation

FROM DRILLING PILOT HOLE TO THE FINAL REAMING

A presentation of the complete drilling package from Rockpecker. Find out product features and how they can complement your drilling rig for increased performance and convenience.

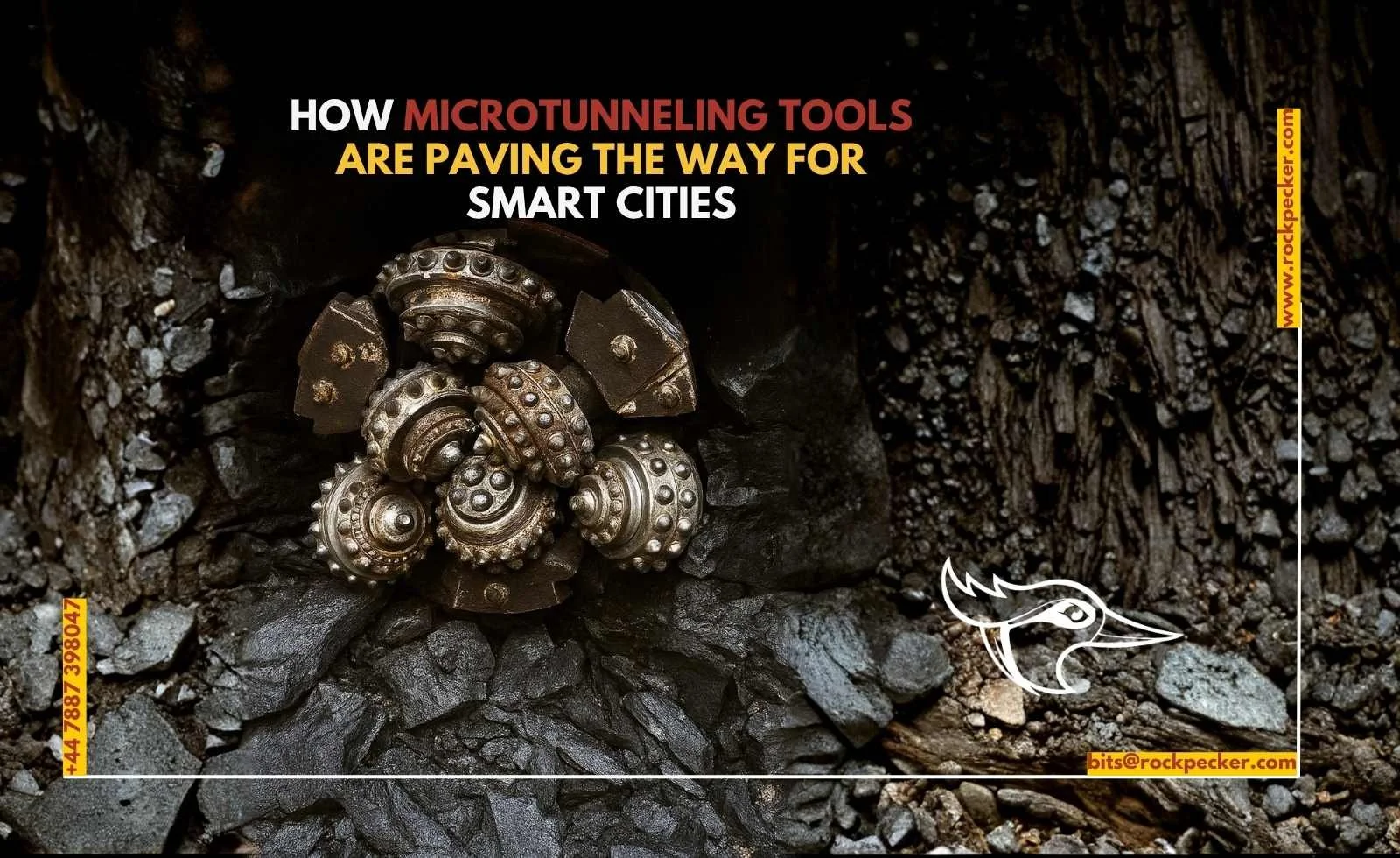

Complete Behind-The-Scenes of a PDC Bit Manufacture

FROM START TO FINISH

Discover how the advanced machinery at the Rockpecker Manufacturing Unit transforms a piece of hardened-steel into one of the most robust rock-drilling tools in the world.

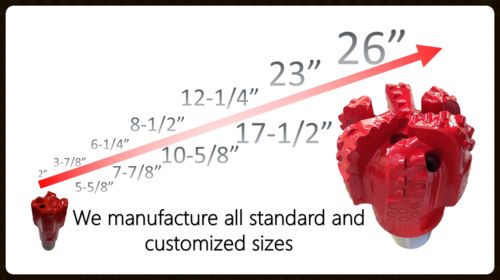

We make it for you.

We'll build you a professional custom made PDC Bit for an economical price with guaranteed satisfaction! Your choice and selection to buy the best performing bit up to 26-Inches!

Best in class technology.

Rockpecker products are designed by a flock of design engineering experts on the board.

Why we stand out.

Produced under the supervision of experienced design & manufacturing engineers, Rockpecker PDC Bits ensure high drilling performance to the drilling professionals across the world.