Directional Drilling And The Advances In Drilling Technology

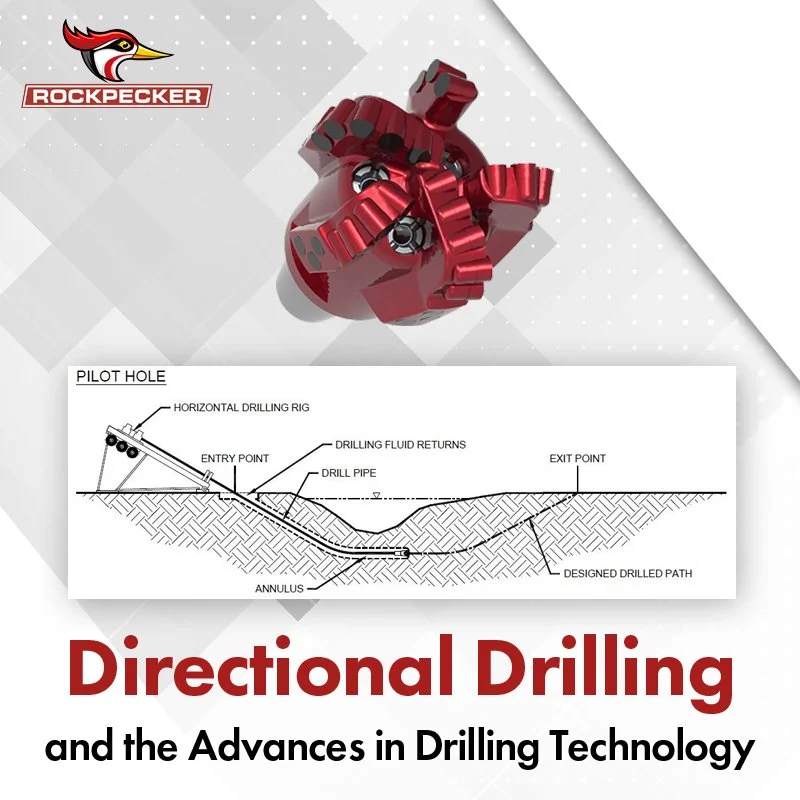

/Directional drilling has gained significant popularity as a technique to get otherwise hard to access natural gas or oil embedded in shale. It does so by controlling the path of the wellbore by manipulating the angle of the PDC bit, as opposed to simply drilling straight down.

Directional drilling involves any attempt to intentionally divert the path of the wellbore and is almost always done to access otherwise difficult-to-reach deposits, such as under a lake or mountain. Using a PDC bit, the wellbore first goes straight down to a predefined depth. When the drill is pointed at the desired angle the force needed to progress through the rock formation comes from the rotation of the PDC bit and the Weight On Bit provided by the drill string. In addition to the special motorized tricone, directional drilling also requires special equipment to measure the progress while drilling. A professional directional driller is essential, and they will require exact knowledge about the progress of the drill bit when determining the course.

A Rotary Steerable System (RSS) is the newest development in directional drilling. It allows for further steering of the bit while the drill string is still rotating and providing force. This negates the need for a motor powering the drill bit itself and reduces the potential areas of failure or mishap. Traditionally, tricone bits have been the go-to choice for directional drilling because they are more easily steerable, although this capacity has recently expanded to PDC bits as well. Rotary Steerable Systems use detailed data on the position of the bit, collected while drilling, to send commands to the bit from the surface. Generally, they will either send carefully controlled variations in the mud column or variations in the drill string rotation, to send a message to the tool powering the bit. This process, while more complicated than conventional directional drilling, offers significant advantages. The rotation of the drill string helps the transport of cuttings or debris to the surface, resulting in less debris and smoother drilling. Additionally, as the steering can be carefully controlled from the surface it allows for more controlled wellbores with smoother surfaces and greater complexity.

Learn more about the capabilities of PDC drilling tools and accessories by browsing through the website.