The Intricacies of Reverse Circulation Drilling Techniques

/Unlike its counterparts, the RC drilling rig leaves an indelible footprint, uncovering the secrets of the Earth in large-diameter wells. This technique, distinctive in its approach, delves into unconsolidated materials with a prowess extending up to 50 inches in diameter and depths of 1000 feet.

Reverse Circulation (RC) is a powerful technique, designed for large-diameter wells in unconsolidated materials. This covers the complexities and practices of reverse circulation (RC) drilling from rig to hydraulic dynamics, showcasing how it balances demands for fluid with unparalleled precision.

Reverse Circulation (RC): Reverse circulation drilling, or RC drilling, is a type of percussion drilling that employs compressed air to safely and efficiently flush material cuttings out of the drill hole. A drilling method where drilling fluid and cuttings are brought to the surface through the inner tube of the drill pipe which is a hollow tube used to transmit drilling fluid and apply rotational force to the drill bit.

1.**Overview of Reverse Circulation Drilling:** RC drilling involves a dual-wall drill pipe system. The outer drill pipe is the conduit for flushing the cuttings, while the inner tube collects samples. The process unfolds in the following steps:

Figure 1: RCD (Reverse Circulation Drilling) with Rockpecker RC Bit

a. Drilling Fluid Injection: High-pressure air or water is injected down the drill pipe, flushing cuttings to the surface.

By injecting compressed air into the drill pipe below water level, the Reverse Circulation Drilling System (RCD), often referred to as airlifting, is an efficient drilling technique that uses circulation to remove slurries and lower the density of the internal water column.

Then, the drill pipe is used to flush the mixture of water, air, and cuttings into settling tanks. Drilling big diameters and deep holes is made extremely effective, safe, and ecologically beneficial when done with RCD Rigs.

RCD is the greatest option for handling any of the following situations if you fit any of them.

- Extensive Diameter—more than 800 mm

- Deep Water (Lower Than 20 Metres)

- Drilling into hard rock (~ 350 MPa)

- Marine Condition Bore Piling.

b. Cuttings Transport:Cuttings travel up the annulus between the inner and outer tubes.

c. Sample Collection: The inner tube captures high-quality samples in a cyclone.

2. Key Characteristics:

a. Rig Design: RC drilling employs a large rig, leaving a substantial footprint, ideal for drilling sizable wells. • Material Excavation: The system utilizes rotary cut and rotary crush actions for efficient material excavation. • Hydraulic Dynamics: Water-based flushing media follows a unique course down the annular space, ensuring effective cuttings removal.

b. Fluid Management:

• Fluid Demand: The process demands a considerable amount of fluid, necessitated by the large settling pit and the need for efficient cuttings flushing.

• Fluid Displacement: The absence of bentonite means the system doesn't create a complete seal, leading to fluid displacement and loss to the original formation.

• Fluid Discharge: Refers to the release of drilling fluid through the nozzles or discharge holes in the RC drill bit, aiding in rock breaking and cuttings removal.

Table 1: Fluid Discharge Mechanism in RC Drill Bits.

3. Tool Types and Sizes:

This single table combines the technical specifications for both RC Hammer and RC Bits, providing a comprehensive overview of their designs, sizes, and performance considerations:

Table 2:Reverse Circulation (RC) Drilling Tools / bits

4. Application and Versatility:

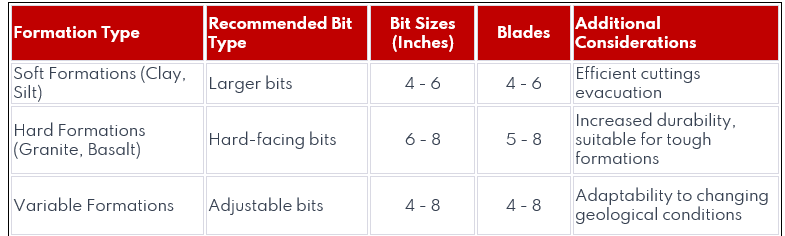

Formation Types: RC drilling is versatile and suitable for various formations, including soft (clay, silt) and hard (granite, basalt). Working Conditions: Adjustable air pressure and fluid injection rates accommodate variable geological conditions. RC drilling is versatile and suits various geological conditions:

Table 3: Bits as per formations for Reverse Circulation (RC) Drilling

5. Advantages of RC Drilling:

• Faster Penetration Rates: Efficient cuttings removal allows higher drilling speeds.

• Sample Quality: The closed system minimizes contamination, ensuring high-quality samples.

• Depth Capability: Suitable for both shallow and deep drilling.

• Development Time: Despite fluid demands, RC drilling accelerates borehole construction, reducing development time compared to traditional methods.

• Precision Cutting: The method excels in precision cutting, crucial for large-diameter wells in challenging geological conditions.

6. Challenges and Mitigations: While RC drilling excels in many aspects, challenges exist:

• Sample Contamination: Proper sealing and design modifications address this concern.

• Depth Limitations: Overcome by using larger-diameter drill pipes and more powerful compressors.

Conclusion:

Mastering the depths with Reverse Circulation Drilling is an art and science. Balancing power with precision, this method redefines the dimensions of drilling excellence. From its unique rig design to hydraulic intricacies, RC drilling proves to be a formidable contender in the exploration of subsurface secrets. Contact us for premium drill bits designed for RCD.