Rockpecker Spiral Stabilizers' Triumph in Irish Water Project and Environmental Impact

/Abstract: This white paper showcases the remarkable performance of Rockpecker's Spiral Stabilizers in the triumph of the Lower Harbour Main Drainage Project in Cork, Ireland. Leveraging the metaphor of the Rockpecker bird's soaring height determined by the depth it drills, this paper illustrates how Rockpecker's 12" and 22" Spiral Centralizers played a pivotal role in the success of the project. The centralizers' exceptional design and performance were instrumental in achieving the longest horizontal drilling in the region and driving an environmentally conscious impact through Trenchless Technology.

Introduction: The metaphor of the Rockpecker bird's height being revealed by its drilling depth resonates with Rockpecker's mission to deliver excellence in drilling solutions. This paper delves into the success of the Lower Harbour Main Drainage Project in Cork, Ireland, where Rockpecker's Spiral Stabilizers shone.

Project Overview: The Lower Harbour Main Drainage Project in Cork marked a significant milestone by achieving the longest horizontal drilling in the region. The project, spearheaded by Irish Water, aimed to eliminate the practice of discharging raw sewage directly into Cork Lower Harbour. By implementing Trenchless Technology, the project sought to minimize environmental impact while ensuring social acceptance and cost-effectiveness.

Rockpecker's Contribution: Rockpecker's involvement in the project was instrumental. The challenge was to design drilling tools for two parallel drills beneath Cork Harbour, requiring the use of spiral centralizers to ensure smooth penetration. Rockpecker's 12" and 22" Spiral Centralizers exceeded expectations, enabling the centralizers to transform pressure into potential and facilitate successful drilling operations. Even after the project, the centralizers exhibited minimal damage and an exceptional Rate of Penetration over a 24-hour period.

Why Rockpecker’s Material Selection Stands Out Rockpecker's commitment to excellence extends beyond innovative design to meticulous material selection. The choice of materials significantly influences the performance, durability, and reliability of drilling solutions. Rockpecker's engineering team employs a rigorous material selection process to ensure optimal centralizer performance under diverse drilling conditions. The provided structural analysis presents a compelling comparison between the materials commonly employed and those meticulously chosen by Rockpecker. The maximum deformation in Rockpecker’s material is around 19 microns. The moment applied on both the materials is equal, but the material selected by Rockpecker deforms about half as the materials commonly used to manufacture stabilizers. That’s why Rockpecker uses the best material out there. The disparities in maximum deformation are vividly apparent:

Figure 1: In the case of the customary materials, the observed maximum deformation approximates 22 microns, accompanied by the above image.

Figure 1a: Contrastingly, Rockpecker's chosen material exhibits a significantly diminished maximum deformation of approximately 12 microns, evident in the above image.

The hardness of Rockpecker’s material is such that it cannot easily wear out even in very hard formations. Please note that greater deformation in the cutting edges of the stabilizer reduces the ROP (Rate of penetration), hence decreasing the efficiency of the drill operation. Also note that these types of deformations increase the wear of the stabilizer, hence decreasing its life.

In a comparative deformation analysis, Rockpecker's Spiral Centralizers were assessed against commonly used materials using structural analysis in ANSYS. The centralizers were simulated under realistic loading scenarios to evaluate how different materials handle stress and deformation. This comprehensive analysis not only validates Rockpecker's material selection but also highlights the superiority of our chosen materials in terms of structural integrity and performance.

The results of the analysis demonstrate that Rockpecker's chosen materials effectively mitigate stress concentrations, resist deformation, and maintain dimensional stability even in demanding drilling scenarios. This rigorous analysis showcases Rockpecker's dedication to engineering centralizers that outperform traditional counterparts, ensuring long-lasting, high-performance solutions for our clients. By leveraging advanced simulation tools and sound material science principles, Rockpecker sets new standards in the drilling industry, ensuring reliability and excellence in every application.

Figure 2: Further accentuating the distinction, the conventional materials reveal a heightened maximum deformation of around 32 microns in the above image.

Figure 2a: Rockpecker's material boasts a remarkably lesser maximum deformation of approximately 19 microns in the image below

Why Rockpecker’s Design Stands Out Rockpecker's design ethos emerges as a beacon of ingenuity, redefining the landscape of drilling technology. A cornerstone of this distinction lies in its adeptness at diffusing stress concentration at critical failure points. Evident in the von Mises stress imagery, Rockpecker's design orchestrates stress distribution with precision, negating the perilous concentration that plagues conventional counterparts.

This strategic prowess not only enhances structural integrity but fortifies against catastrophic failure, reflecting a fusion of cutting-edge engineering insight and meticulous craftsmanship. By ingeniously orchestrating stress dispersion, Rockpecker's design embodies longevity and operational resilience, reaffirming our steadfast commitment to reshaping performance and safety paradigms.

Figure 3: 12Inch Rockpecker Stabilizer

Figure 4: 22Inch Rockpecker Stabilizer

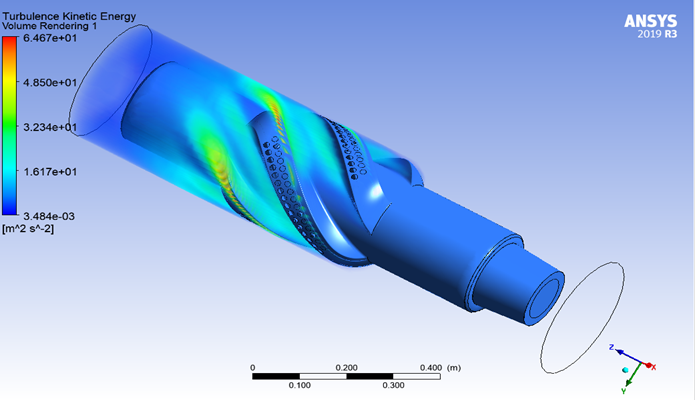

Innovative CFD Insights: Elevating Performance

At Rockpecker, our commitment to engineering excellence extends beyond convention, ushering in a new era of heightened drilling efficiency. A key catalyst in this transformative journey is our adept utilization of advanced Computational Fluid Dynamics (CFD) simulations, casting a pioneering light on our design process. In the presented CFD image, a symmetrical velocity profile emerges, a hallmark of our symphonized design that effectively minimizes vibrations. This harmonious fluid flow dynamic bears testimony to our holistic

Figure 5: Rockpecker Spiral Stabilizer

Further demystifying our design, a strategic orchestration unfolds wherein fluid velocity magnifies precisely where heat extraction is paramount – notably, in close proximity to cutting edges. The accompanying image adds another layer of insight, showcasing a seamless flow that spans a substantial portion of the blade profile. This masterstroke in design ensures not only smoother cutting and stabilizing operations but also culminates in enhanced efficiency.

Figure 6: Integral Blade Spiral Stabilizer or Centralizer

Figure 7: Rockpecker Stabilizer or Centralizer

However, our innovation extends beyond mere smoothness. Toward the blade's end, a deliberate surge in turbulence materializes, strategically harnessed to reduce drag. This calculated turbulence infusion stands as a testament to our pursuit of increased Rate of Penetration (ROP), magnifying the overall operational prowess of our solution. In embracing advanced CFD techniques and nurturing a profound understanding of fluid dynamics, Rockpecker emerges as an exemplar of innovative engineering. The symmetrical velocity profile, the precision in heat distribution, and the strategic turbulence culmination collectively shape a paradigm where performance and efficiency reach new zeniths. Environmental Impact: By facilitating Trenchless Technology, the Lower Harbour Main Drainage Project significantly reduced emissions and environmental impact. This sustainable construction approach aligns with global efforts to combat climate change and raise environmental awareness. The success of this project translates into a lower environmental impact on the planet by curbing the practice of raw sewage discharge. Acknowledgment: Ross Henderson of O’Connor praised Rockpecker's crucial role in this breakthrough trenchless project. Rockpecker's dedication to delivering excellence and driving success in environmentally conscious projects positions it as a leader in the field. Conclusion: The Lower Harbour Main Drainage Project's triumph stands as a testament to Rockpecker's Spiral Stabilizers' exceptional performance and the impact of Trenchless Technology on environmental preservation. Rockpecker's commitment to innovation and sustainability positions it as a driving force in the realm of drilling solutions, with a continuous focus on delivering excellence worldwide. For more information on Rockpecker's Spiral Stabilizers and their contributions, please contact our team at Rockpecker.

About Rockpecker: Rockpecker is a pioneering provider of innovative drilling solutions for diverse industries. With an unwavering commitment to technological advancement and environmental stewardship, Rockpecker continues to redefine drilling performance and efficiency on a global scale.