Tricone Selection: Recognizing the Subtleties for Optimal Drilling Performance.

/Having spent ample time in the trenches, we've come to understand that there's no substitute for the right tool, particularly with tri-cone bits. Whether dealing with the softest shales or the most resilient granites, a driller's intricate knowledge of tricone bits can mark the difference between efficiency and perpetual challenges. Here's an insight into the selection process from an expert's viewpoint.

Introduction to Tricone Bits: A tricone bit isn't just any drilling tool, it's an intricately designed tri-headed apparatus that interacts with the Earth's strata in complex ways. Tricone bits consist of three rotating cones that have teeth made of a hard material, usually steel, tungsten carbide, or diamond. These teeth crush the rock as the cones rotate, and the rock debris is then cleared away by the drilling fluid.

Figure 2- Tricone Selection: Recognizing the Subtleties for Optimal Drilling Performance.

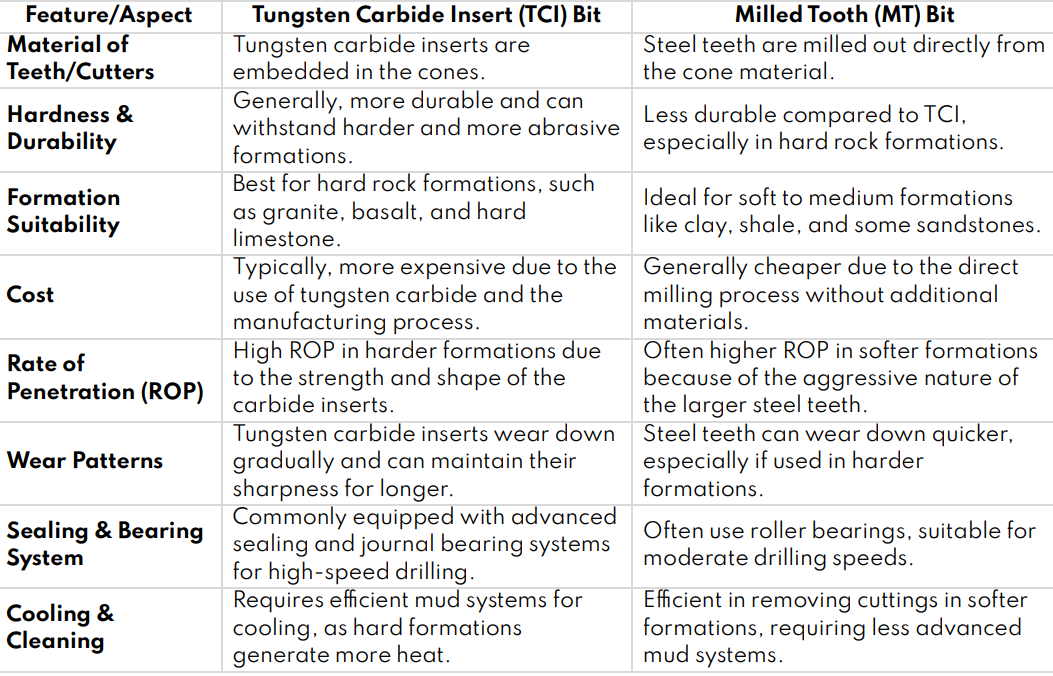

Types of Tricone Bits:

* Milled-Tooth Bits: These have steel teeth that are milled into the cones. They're generally used for softer formations.

* Tungsten Carbide Inserts (TCI) or Insert Bits: These bits have tungsten carbide inserts placed into drilled holes in the cones. They are more durable and used for harder formations.

The choice between TCI and MT tricone bits often depends on the specific requirements of a drilling project, including the rock formation, drilling depth, and available equipment. Always consult with drilling experts and consider local conditions when selecting a bit.

Figure 2: Comparison between TCI and Mill tooth Tricones

Figure 3: Mill tooth- MT V/S TCI Tricone Bit

Figure 4:Rockpecker TCI Tricone Bit

Understanding IADC Codes: Remember, while the IADC code provides a solid starting point, always consider local conditions, rig capabilities and specific drilling objectives when selecting a bit. The above points offer a general overview, and the exact specifications and recommendations can vary based on the manufacturer and specific drilling needs.

Figure 5: Tricone Bit Selection Criteria for Different Soil Formations

The International Association of Drilling Contractors (IADC) has a coding system that helps drillers choose the correct tricone bit for the specific rock formation. The code typically has three numbers, where:

- The first number indicates the rock formation (1-softest to 8-hardest).

- The second specifies the formation type, Generally, a higher number means more abrasive rock or more interbedded formations.

- The third indicates the bit type, with 1 being a steel tooth and 2 for tungsten carbide.

Integrated aspects of Tricone Bits geometry and the applications mentioned are standard uses for these components:

Figure 6: Tricone Bits' geometry and applications

Weigh in Other Factors:

- Balanced cutting structure: Cutting structures and bearing geometry that are optimized enable constant load distribution, resulting in consistent penetration rates and minimizing bearing failure hazards. Furthermore, the extensive protective coating saves wear on the bit body and shirt tail.

- Drilling Depth: Deeper wells often require more durable bits, like TCIs.

- Drilling Speed: Faster drilling might favor a specific type of bit or tooth configuration.

- Budget: While TCI bits are more durable, they also come with a heftier price tag.

Whether you're venturing into the drilling industry or you're a seasoned pro, selecting the appropriate tricone bit is pivotal to your project's success. With countless options available, making the right choice can seem overwhelming. Fear not, you can always rely on expert advice as well as Rockpecker drilling tools as well and this step-by-step guide is crafted to simplify this very task.