Ensuring Stability and Reducing Stress in Drilling Operations

/with Rockpecker Centralizer & Stabilizers

Centralizers are paramount in hole-opening drilling operations, ensuring that the casing is meticulously centred within the wellbore. By optimizing the placement of the casing and minimizing points of stress, Rockpecker centralizers/stabilizers offer a plethora of benefits, from enhancing cementing processes to ensuring the well's structural integrity.

At times, the front of a hole opener may self-centralize, while in other instances, a centralizer might be needed to shift the hole opener closer to the center point. Additionally, placing a stabilizer behind the tool ensures the hole opener remains parallel to the pilot hole, thus boosting its performance.

Figure 1: Rockpecker Stabilizer

Figure 2: Rockpecker Centralizer

Impact of having Centralizer/ Stabilizer on Drill Hole Assembly

Centralizers

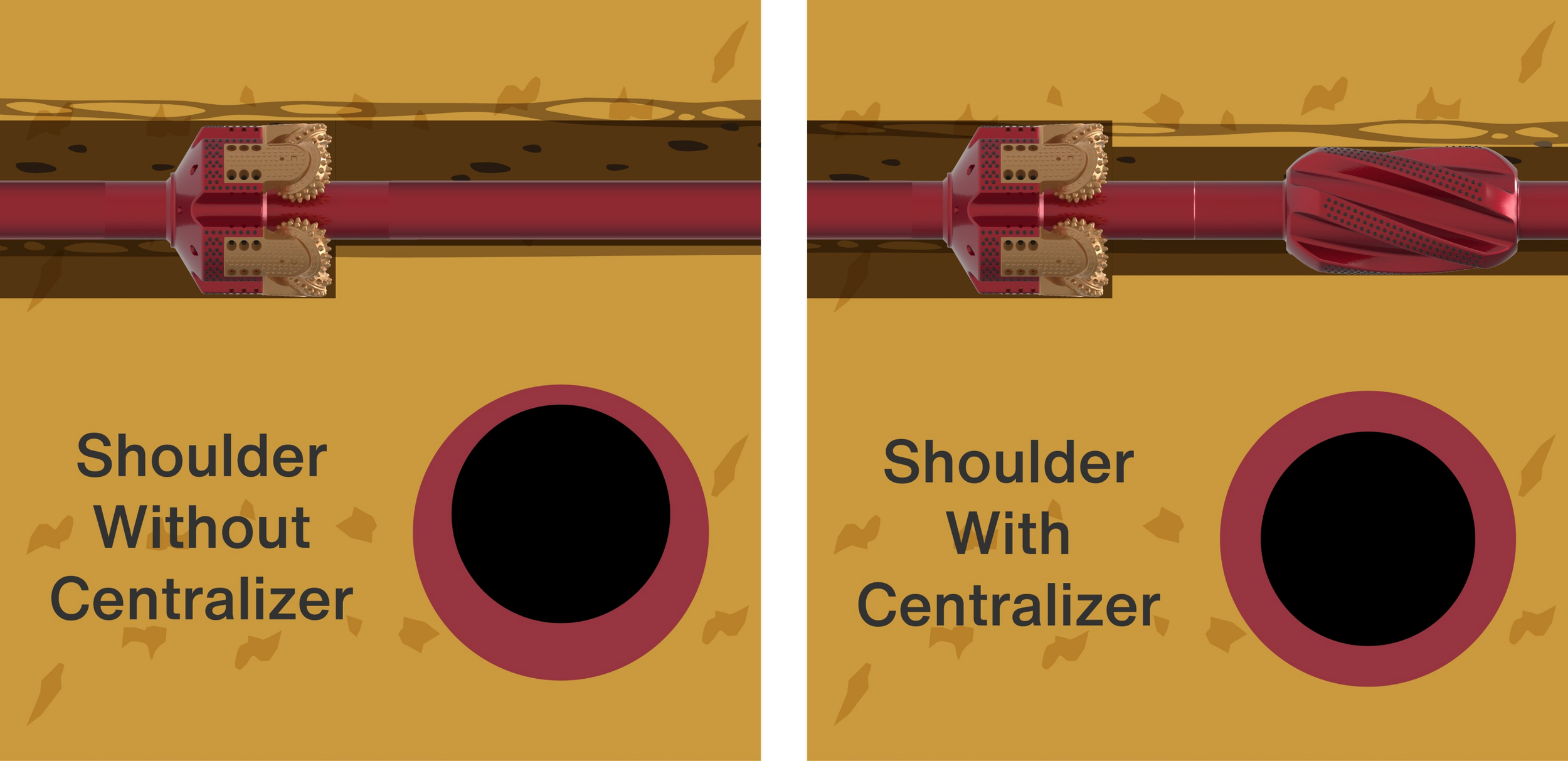

The objective is to keep the Hole Opener as close to the center of the pilot hole as possible to have an even-cutting shoulder. This keeps the bearing under a more balanced load, minimizing torque and extending cutter life.

o Stress Alleviation: The drill hole assembly is safeguarded against concentrated stress points, preserving the desired drilling path. This equates to fewer complications, time savings, and reduced operational costs.

o Improved Structural Integrity: By distributing stress more evenly, centralizers improve the well's structural integrity, minimizing risks of premature wear or breaches in the casing.

- Uses: Maintaining a tool square against the shoulder enhances performance and increases cutter life. o Designed to keep the casing centered within the wellbore. o Ensure uniform annular space for even cement slurry distribution. o Aid in achieving optimal zonal isolation and prevent fluid migration. o Minimize wear on the casing by preventing direct contact with the wellbore. o Reduce the risk of differential sticking. o Enhance the smoothness of drilling operations.

• Placement: Centralizers are affixed at regular intervals along the casing string and in front of the Hole Opener in the. Their frequency is determined based on wellbore geometry, casing specifications, and other factors. They are especially vital at the joints or connections between casing segments and at certain calculated positions to ensure effective centralization throughout the wellbore.

Figure 3: Effects of reaming without V/S with Centralizers

Stabilizers

• Uses: Stabilizers help distribute the mechanical stress induced during drilling operations, mitigating the risk of casing deformation or failure. Bend and stress can be decreased by properly positioning a stabilizer joint behind the hole opening. As the hole opening size increases, the use of a centralizer becomes more crucial, since the drill pipe tends to drop further in larger holes.

o Integrated into the drill string to maintain the desired hole trajectory. o Prevent undesired vibrations and stabilize the drill bit. o Ensure hole quality and optimize the rate of penetration. o Provide a broad contact area with the wellbore, reducing drilling deviations. o Minimize drilling dysfunctions like hole spiralling or borehole enlargement. o Crucial for maintaining drilling accuracy and equipment integrity.

Figure 4: Reaming without Stabilizer

Figure 5: Benefits of having a Stabilizer

• Placement: Stabilizers are strategically positioned within the bottom hole assembly (BHA), which is the lower part of the drill string. They are usually placed near the drill bit to maintain its trajectory and can also be placed at other intervals in the BHA to manage vibrations and ensure stability. The number and position of stabilizers depend on the specific drilling plan, hole geometry, and expected challenges.

Rockpecker's centralizers and stabilizers stand out in this domain, offering unmatched benefits ranging from enhanced cementing processes to guaranteeing the structural fortitude of wells. These tools, when employed correctly, not only ensure the efficiency of the drilling process but also safeguard the integrity and longevity of the well.

Intrigued by the world of drilling enhancements and keen on maximizing your drilling operations? Reach out and let's unearth the possibilities together.